Machining & Fabrication

The fabrication process is devided into:

- Computer-Controlled Machining

- Computer-Controlled Cutting

- 3D Printing

- PCBs Milling

Computer-Controlled Machining

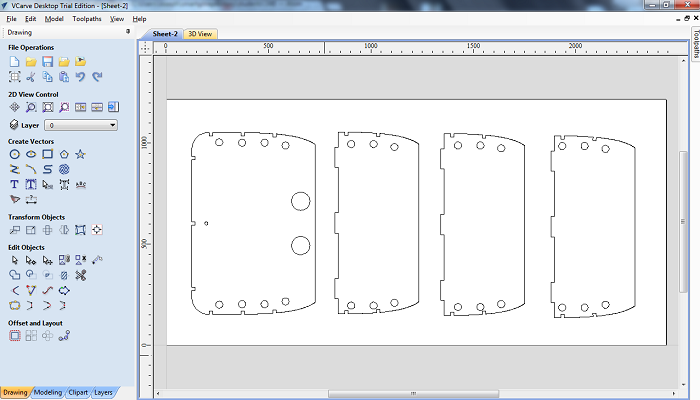

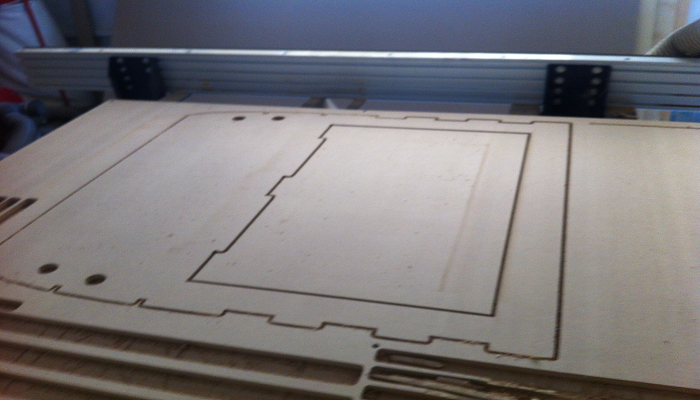

Finally its time to fabricat the main part of the project. First I extracted the the shell CAD files into DXF so I can use them on VCarve to be ready for the Shopbot.

CNC Cutting Process

Computer-Controlled Cutting

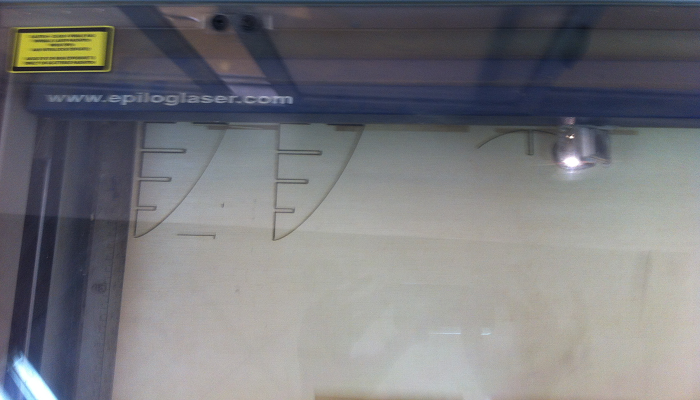

At this process the nose cone parts was cut using 1 plywood sheet by the laser cutter machine.

Laser Cutting Process

3D printing

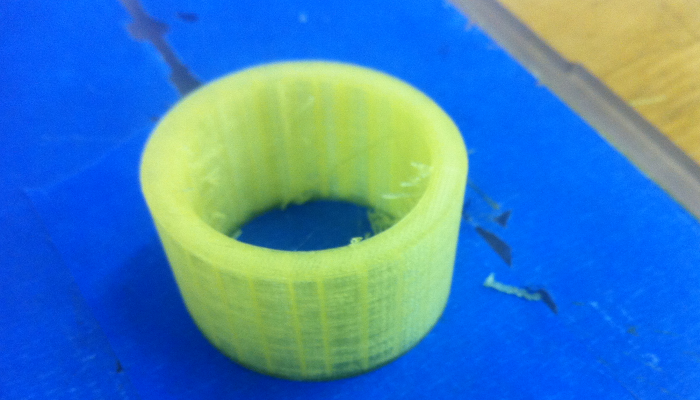

At this process the mounted ball bearing was printed using 12gm of PLA.

3D Printing Process

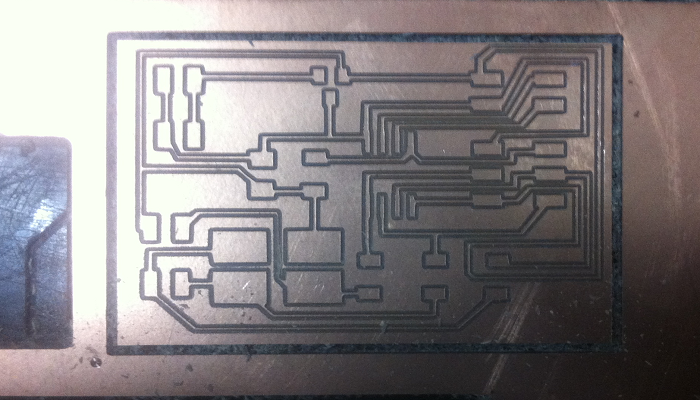

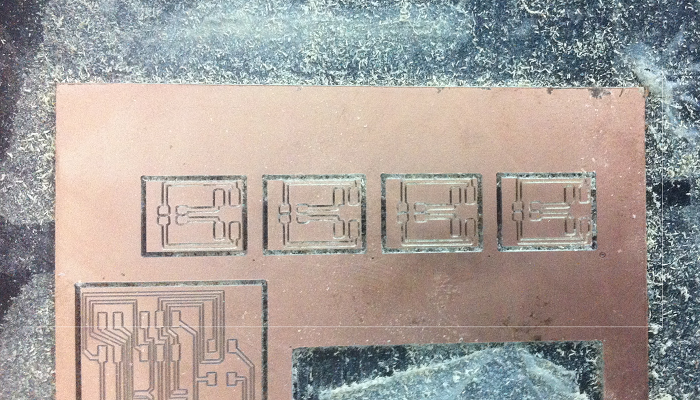

PCBs Milling

At this process the Bridge and Nodes PCSs were milled using Roland MDX-20 Modela.

Milling Process

Bridge board Testing

Nodes boards Testing

This work by Joseph Gourgy is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.